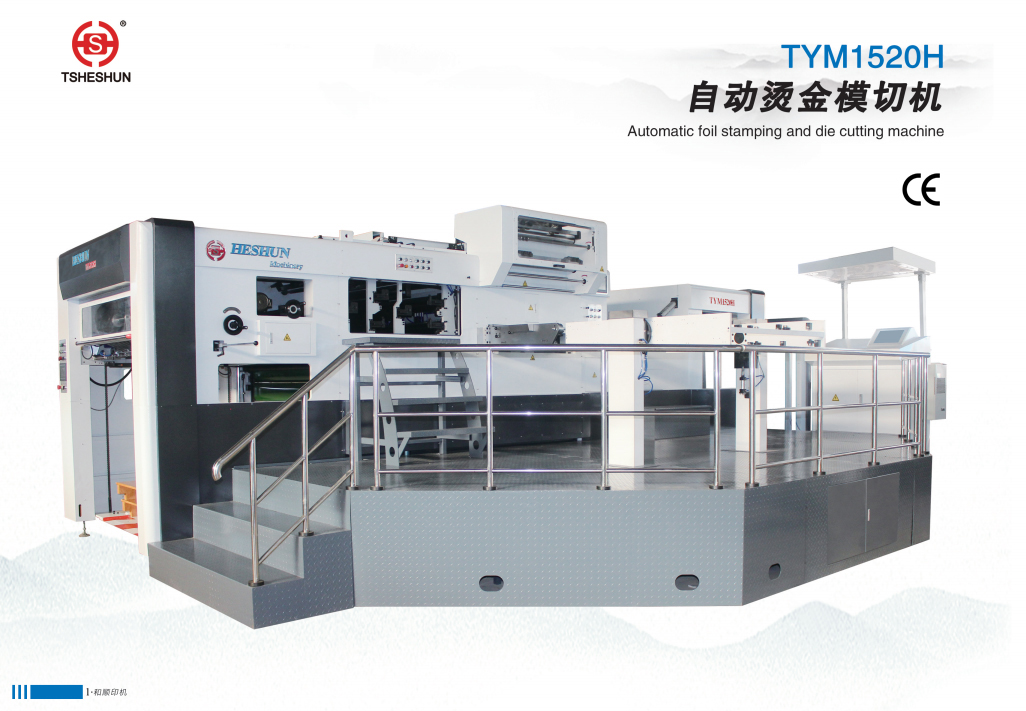

Product introduction:

| Max.Paper size: | 1520×1130mm | Min.Paper size: | 450×360mm |

| Max.Diecutting size : | 1510×1110mm | Top speed: | 5500S/h |

| L.Max.foil stamping size : | 1500×1100mm | Transverse maximum gilding size: | 1490×1100mm |

| Max.Height of feeding pile: | 1700mm | Maximum height of recoiving pile: | 1500mm |

| Highest gilding speed: | 5000s/h | Maximum working pressure: | 6000KN |

| Paper processing thickness: | 紙板0.1-1.5mm;E型瓦楞紙≤4mm | Temperature setting range: | 0-199℃ |

| Maximum gold foil diameter: | 210mm | Number of heating zone: | 20 |

| Electric heating power: | 38.5KW | Total power: | 88.95KW |

| Weight: | 39000KG | Overall dimansion(L×W×H): | 11000×6800×3100mm |

|

Features: |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

Phone:13832899410

Tel:0315-6381286

Fax:0315-6381286

E-mail:171201474@qq.com

Address:Zhendingfu Village East, Huandao, Yubin highway, Chengxi, Yutian County, Hebei Province